In your daily life, what should you do when your phone dropped to water, sometimes, maybe it cannot be used again, but normally, you can still use it just need to repair it

Solution 1. Don't turn on the iPhone

Solution 1. Don't turn on the iPhone

When your iPhone dropped into the water, you should keep in mind that don't turn on the device, immediately. Maybe your device would turn off after being damaged by water, no matter when, don't turn it on manually at this time. When you turn on it, if the water has reached inside the device, it might cause more damage to your phone than good. So, in order to minimize the damage your phone receives, it is best not to open your iPhone.

Solution 2. Remove the iPhone case

The next step is removing any protective case, if your iPhone has them. The iPhone case at other times will play a protective role for our iPhone, but after the iPhone into the water, you must take it off.

Solution 3. Remove the iPhone SIM card

When you turn off your iPhone, you must make sure the water won't damage the SIM card. So you must remove the headphones and the SIM card tray on the iPhone side, the Sim ejector tool will help you. In addition, don't insert the tray back and leave the slot open.

Solution 4. Handle water stains

You must wipe the iPhone exterior, taking the assistance of cotton cloth. Don't apply too much pressure while wiping the phone to minimize the iPhone water damage, it can avoid spreading the liquid around.

You can shake the iPhone and you can blow into the iPhone openings. You can also try compressed air or a blow dryer on cool. You can also try using a wet / dry vacuum to suck the water out.

Solution 5. Put the iPhone in a dry place

After clearing its exteriors, you need to place the iPhone in a warm and dry place. This would evaporate the water content that is inside the iPhone.

Don't make it exposes to too much sunlight, instead put it on the top of a TV or a monitor. It can protect your iPhone won't get damaged due to extreme exposure to sunlight.

Don't make it exposes to too much sunlight, instead put it on the top of a TV or a monitor. It can protect your iPhone won't get damaged due to extreme exposure to sunlight.

Solution 6. Repair it

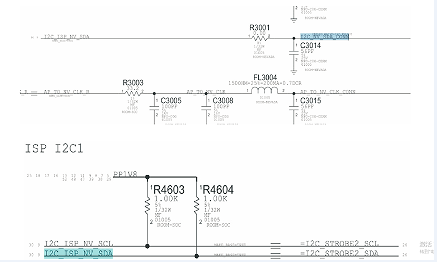

When done the above steps, the last step is repairing the water damaged iPhone. You must repair it by yourself or other professional phone repair man. They will use a lot of mobile repair tools to resolve your iPhone. Such as the VIPFIX phone toolkit to disassembly the iPhone, the titanium alloy tweezers to check the phone parts and components, the LCD screen suction cup to open the iPhone LCD, the VC890D digital multimeter to measure the current, the SAIKE 898D soldering iron to weld the motherboard chip, etc.